Qiming Casting Gyratory Crusher Liners: 9 Unique Features

The importance of robust and reliable equipment cannot be overstated in mining and quarrying, where efficiency and productivity are relentlessly pursued. At the heart of many crushing operations lies the gyratory crusher, a powerhouse of a machine designed to pulverize tough materials with unparalleled efficiency.

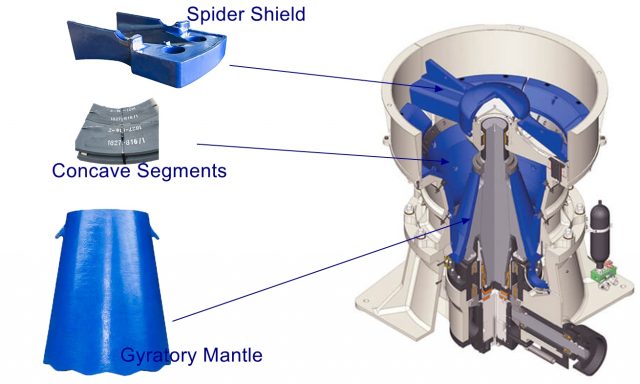

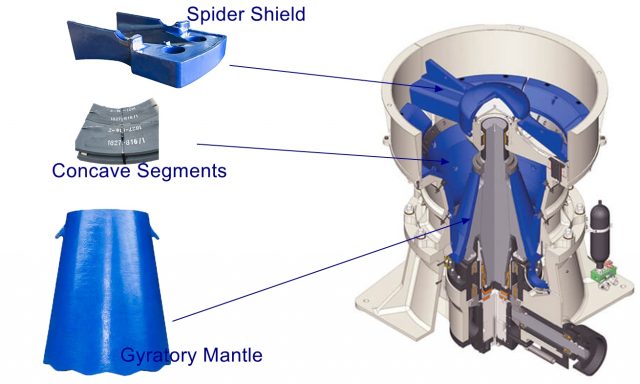

Yet, behind the formidable exterior of these crushers lies a critical component that often goes unnoticed but plays a pivotal role in ensuring their longevity and performance: the gyratory crusher liners.

At Qiming Casting, we take immense pride in crafting high-quality wear-resistant solutions for the mining, quarrying, cement, coal, and metal recycling industries. A testament to our commitment to excellence and innovation is our range of gyratory crusher liners.

In this article, we delve into the unique features of our Gyratory Crusher Liners that set them apart in the competitive landscape.

9 Amazing Features of Qiming Casting Gyratory Crusher Liners

Tailored, Graded, and Durable

Our Gyratory Crusher Liners are meticulously designed to provide tailored, graded, and durable wear-resistant solutions. We understand the critical role that crusher liners play in safeguarding the longevity and efficiency of crushing machinery.

That’s why each liner is crafted with precision to match the specific concave profile and configurations of the machinery it serves.

High Impact and Abrasion Protection

One of the hallmarks of our gyratory crusher liners is their unparalleled ability to withstand high impact and abrasion. Operating in rugged environments, gyratory crushers are subjected to extreme forces. Our liners act as a shield, protecting the crusher’s mainframe and ensuring uninterrupted operation even in the harshest conditions.

Made of High Manganese Steel

Our gyratory crusher liners are primarily fabricated using high manganese steel, renowned for its exceptional hardness, toughness, and abrasion resistance. This unique material composition enables our liners to endure the rigors of abrasive crushing without compromising the efficiency or performance of the crusher.

Customization for Maximum Efficiency

We recognize that no two crushers are alike, and that’s why our liners are fully customized to match the machinery’s concave profile and configurations. This bespoke approach ensures optimal fitment and functionality, ultimately translating into enhanced efficiency, reduced downtime, and extended wear life.

Premium Grade Materials

When it comes to quality, we spare no expense. Our gyratory crusher liners are crafted from premium-grade manganese steel, sourced from reputable suppliers. This ensures consistent quality, reliability, and performance across our product range, instilling confidence in our customers’ operations.

High Impact Strength and Durability

Durability is non-negotiable in the mining and quarrying industry, where equipment is subjected to relentless wear and tear. Our gyratory crusher liners boast high impact strength and exceptional durability, capable of withstanding the most demanding operating conditions with ease.

Erosion Prevention for Extended Uptime

Erosion can significantly impact crusher performance and uptime. Our liners are engineered with 100% erosion prevention in mind, effectively shielding the machinery from the deleterious effects of abrasive material. This translates into extended uptime, reduced maintenance requirements, and lower overall operating costs.

Incorporation of Titanium Carbide Inlay Rods

To further enhance the hardness and wear resistance of our liners, we incorporate Titanium Carbide Inlay Rods into select designs. This innovative approach significantly increases the hardness of the manganese steel, making our liners ideally suited for extreme operating environments where conventional materials fall short.

Longer Wear Life, Reduced Maintenance Costs

By choosing Qiming Casting gyratory crusher liners, our customers benefit from longer wear life, ultimately leading to reduced maintenance time and costs. Our liners are engineered to withstand the rigors of continuous operation, ensuring uninterrupted production and optimal equipment performance.

In conclusion, Qiming Casting gyratory crusher liners epitomize innovation, quality, and reliability. With their tailored design, high-grade materials, and unparalleled durability, our liners offer unmatched protection and performance in the most demanding applications.

Whether you’re operating in the mining, quarrying, cement, coal, or metal recycling industry, you can trust Qiming Casting to deliver superior wear-resistant solutions tailored to your specific needs. Experience the Qiming Casting difference today and elevate your crushing operations to new heights of efficiency and productivity.